PET MET Laminates

PET MET Laminates Specification

- Product Type

- Laminated film

- Material

- Polyester (PET), Metallized polyester

- Type

- Flexible packaging laminates

- Style

- Metalized overlay

- Packing Format

- Rolls or sheets

- Hardness

- Medium

- Filling Capacity

- N/A (used for packaging lamination, not direct filling)

- Tensile Strength

- 170 MPa (MD)

- Size

- Customizable as per requirements

- Dimension (L*W*H)

- Varies based on roll width and length; common widths: 250mm-1250mm

- Color

- Silver/metallic

- Moisture Barrier

- Excellent

- Usage

- Snacks Packaging, Confectionery, Food, Pharma, Gift Wraps, Industrial Applications

- Thickness

- 10 - 50 microns (customizable)

- Food Grade

- Yes (Complies with FDA/EC regulations)

- Recyclability

- Depends on the laminate structure

- Gas Barrier

- Superior (for O2 and aroma retention)

- Sealing Compatibility

- Heat Sealable (with/without coating)

- Heat Resistance

- Up to 180°C

- Opacity

- High (due to metallization)

- Length per Roll

- Standard or customized (usually 1000m to 6000m)

- Surface Finish

- Metallized, High Gloss, Smooth

- Core Inner Diameter

- 76 mm (3 inches)

- Printability

- High (suitable for printing and lamination)

PET MET Laminates Trade Information

- Minimum Order Quantity

- 2000 Kilograms

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 2000 Kilograms Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About PET MET Laminates

Excellent Barrier Properties

PET MET Laminates provide outstanding moisture and gas barrier capabilities, making them the ideal choice for packaging products sensitive to oxygen and aroma loss. Their metallized layer ensures contents remain fresh and protected from external contaminants during storage and transit.

Customizable for Diverse Needs

Available in thicknesses ranging from 10 to 50 microns and widths from 250mm to 1250mm, these laminates are crafted to meet specific packaging requirements. Both roll and sheet packing formats are offered, with roll lengths customizable as per client demand to ensure efficient production and packaging processes.

Superior Printability and Heat Resistance

The high-gloss surface allows for vibrant, precise printing, enhancing product branding and shelf impact. PET MET Laminates withstand temperatures up to 180C, permitting reliable heat sealing, even in demanding packaging lines.

FAQs of PET MET Laminates:

Q: What are PET MET Laminates and what makes them suitable for food and pharma packaging?

A: PET MET Laminates are flexible packaging materials made from metallized polyester (PET), offering high gloss, smooth finishes, and excellent barrier properties. Their food grade certification (FDA/EC compliant), high opacity, and superior moisture/gas barriers ensure product freshness, making them well-suited for food and pharmaceutical applications.Q: How customizable are the dimensions and thickness of PET MET Laminates?

A: The dimensions of PET MET Laminates are fully customizable to fit specific requirements, with common widths ranging from 250mm to 1250mm and thicknesses between 10 to 50 microns. Roll lengths and formats can also be adjusted as per customer needs, typically from 1000m to 6000m.Q: What is the process for printing and laminating on PET MET Laminates?

A: PET MET Laminates are engineered for exceptional printability, supporting various printing techniques like rotogravure and flexographic printing. Their smooth, high-gloss metallized surface ensures excellent ink adhesion and vibrant results, suitable for subsequent lamination and finishing steps.Q: Where are PET MET Laminates commonly used and what are their primary benefits?

A: These laminates are widely used in snack food packaging, confectionery, pharmaceuticals, gift wraps, and numerous industrial applications. Their key benefits include high barrier protection against moisture and gases, robust heat resistance (up to 180C), and compatibility with most heat-sealing machinery.Q: How does the metallization of PET MET Laminates enhance product protection?

A: The metallized layer significantly boosts the opacity and barrier performance of the laminate, effectively blocking light, moisture, oxygen, and odors. This preserves product quality, extends shelf life, and protects sensitive items during transport and storage.Q: Is PET MET Laminate suitable for recycling and how does laminate structure affect this?

A: Recyclability depends on the overall structure of the laminate. While base PET is recyclable, the presence of metallization and additional layers may limit recyclability. Clients interested in sustainable options can discuss specific structure requirements to improve recyclability.

Price 250 INR/ Kilograms

- Minimum Order Quantity

- 2000 Kilograms

- Supply Ability

- 2000 Kilograms Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Material Category

Biscuits Packs

Price 50000 INR / Kilograms

Minimum Order Quantity : 2000 Kilograms

Hardness : Other, Soft Pack

Product Type : Other, Biscuits Packaging

Size : Standard/Customized

Packing Format : Other, Pouch Pack

Confectionery Packaging Material

Price 250.00 INR / Kilograms

Minimum Order Quantity : 5000 Kilograms

Hardness : Other, Soft / Flexible

Product Type : Other, Packaging Film for Confectionery

Size : Customizable

Packing Format : Other, Roll Film

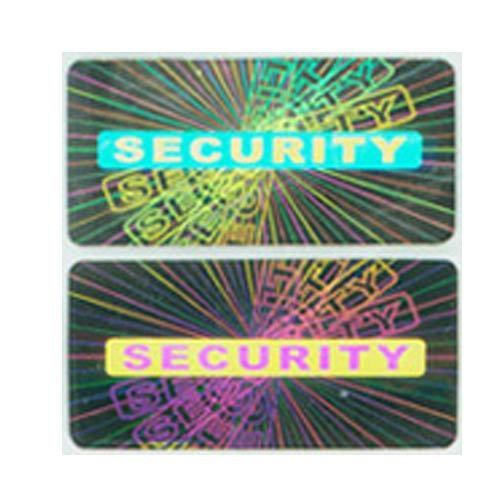

Holographic Packaging Laminates

Price 250.00 INR / Piece

Minimum Order Quantity : 2000 Pieces

Hardness : Other, Soft, flexible material

Product Type : Other, Holographic Packaging Laminate

Size : Customizable, standard widths from 300mm to 1200mm

Packing Format : Other, Rolls or sheets, as per customer requirements

Biscuits Packaging Pouches

Price 150.00 INR / Kilograms

Minimum Order Quantity : 5000 Kilograms

Hardness : Other, Soft / Flexible

Product Type : Other, Biscuits Packaging Pouch

Size : Available in Standard & Custom Sizes

Packing Format : Other, Pouch